A、General condition:

1、Type:

TLZ- II continuous casting & rolling production line for lower-oxygen copper rod

2、Technical feature of CCR line:

Continuous casting & rolling production line for lower-oxygen copper rod uses copper cathode plate or copper scrap as raw material and mainly produces Φ8mm bright and low-oxygen copper rod. Product range: Φ8mm-Φ20mm. Its technological characteristics are continuous production, high output and low production cost. Shaft furnace is used when electrolytic copper plate is used as raw material, Lafarge tilting furnace or reverberatory furnace is used when scrap copper is used as raw material. Other parts of the unit are the same.

The copper rod produced by the machine conforms with GB/T3952-2008 standard.

3、Main technical process:

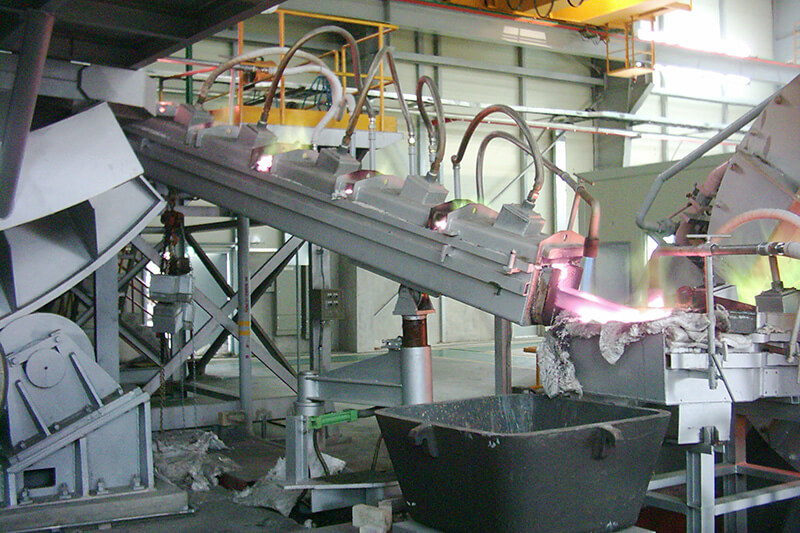

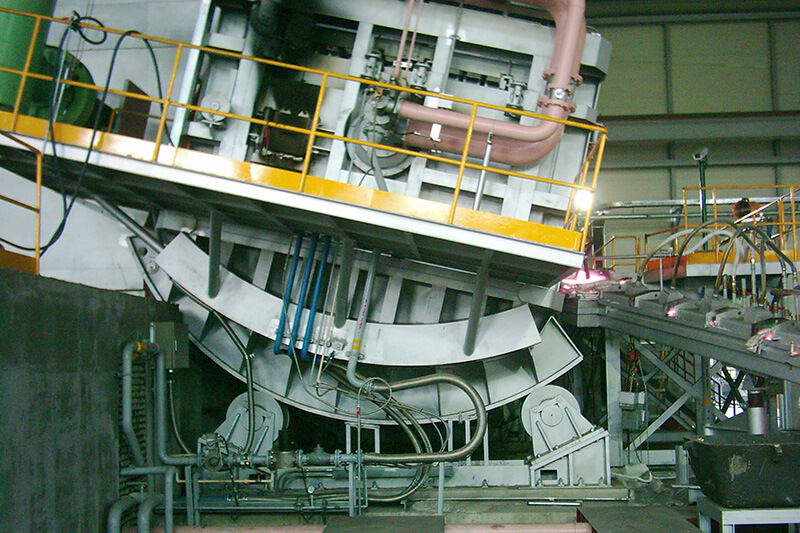

Copper cathode plate→shaft furnace(continuous melting)、or La Farga furnace tilting furnace,or reverberatory furnace(melting and smelting)→holding furnace、launder→ pouring ladle→five-wheel type continuous casting machine→ front traction device→ rolling shear→straightening chamfering machine→feeding device→ double-roller continuous rolling machine → copper rod reduction & cooling system→ waxing device→rear haulage device →hydraulic coiling take up device→hydraulic packing→warehouse

B、Main technical parameters:

1. Copper rod diameter: 8mm-20mm

2. Ingot cross section: 1800-6500mm2

3. Crystallization wheel diameter: 1800-3000mm

4. Rolling numbers: 10-14

5. Production Capacity/hour: 12-35T

6. Holding furnace capacity: 7-36T

C、Main machine composition:

1. Shaft furnace(copper cathode plate), or La Farga furnace tilting furnace(copper scrap), or reverberating furnace(copper scrap),choose one kind

2. Upper launder

3. Tilting holding furnace

4. Five-wheel type continuous casting line

5. Ingot traction device

6. Rolling shear

7. Unloading device、lifting launder and straightening device

8. Trimmer and polisher

9. Feeding device

10. Continuous rolling machine

11. Pickling device

12. Arc rolling way

13. Copper rod traction device

14. Wax device

15. Coiler

16. Winding device

17. Lifting desk

18. Packing device

19. Pallet, conveyor, compressing and lifting table way

20. Hydraulic system

21. Electrical part